When 3D printers were first developed in the 1980s, designers were one of the first groups to recognize the amazing potential of this new technology. 3D printing allows designers to be nimbler, more fluid, and take more risks with fewer consequences. With 3D printing, designers can start testing their models in real-world situations within a few hours of drawing them in a CAD program.

In an industry where success can be measured in microns, rapid prototyping is an invaluable tool. Yet, with all of its impressive capabilities, not all design firms are equally positioned to benefit from the power of 3D printing.

This article explores how various design organizations are taking advantage of the power of 3D printing, and considers what questions you should ask yourself before implementing a 3D printing program in your organization.

How Are Designers Using 3D Printing?

While there are as many unique uses for a 3D printer as there are unique design firms, learning how other design firms are using 3D printing is a good way to help formulate some ideas as to how you can put a printer to work in your organization.

Prototyping

Currently, prototyping is the most commonly cited reason for beginning a 3D printing program. When using a 3D printer to prototype, you can test an actual real-world model of your design within a few short hours of its design completion.

With a 3D printer, if you find that you need to make a tweak to your design, no problem. Just go back to your CAD design, make your adjustments, and print out a new model. Design. Print.

Test. Tweak. This process can be completed over and over again until your prototype is just what you are looking for.

Another benefit of prototyping with a 3D printer is that it is quick and easy to create multiple iterations of your design. This way, you can test several designs in the field to discover which iteration performs the best in a real-world situation.

With 3D printing, you are able to fail faster. The sooner you know that a design won’t work, the sooner you can begin troubleshooting, allowing you to arrive at your final product sooner.

Creating Models

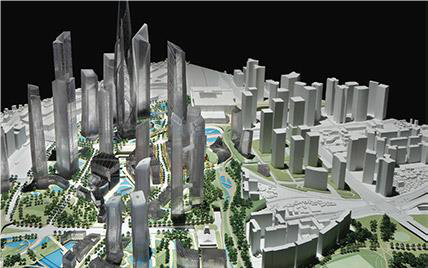

3D printed models are a great way to translate your vision to your clients or co-workers, ensuring that every team member is on the same page during each stage in the design cycle. From architects to furniture makers, designers of all sorts can benefit from a faster, cheaper, more efficient model-making method.

Small Scale Manufacturing

In many cases, manufacturers find that using a 3D printer for a small run of parts is more cost-effective than traditional manufacturing methods.

Even for organizations that don’t do any in-house manufacturing, there are plenty of places that you can find cost savings in small runs of parts. Items like clips and brackets, for example, can often be created in-house, leading to some pretty impressive savings.

Marketing

A desktop printer is a simple and effective way to create custom marketing materials and giveaways. From keychains with your logo to custom business card cases, there are many, many ways that you can keep your customers engaged with your company through 3D printed materials.

Printing Will Become Your Answer

Once you have a 3D printer, you will find yourself saying, “Let’s just 3D print it!” You will probably be saying this a lot. You will also find that the printer becomes your go-to solution for fixing any little annoyances around the office.

Ready to Get Started? Questions to Ask Yourself First.

What is your budget?

Before you even begin to look at printers, you must have an idea as to how much you would like to spend. When it comes to 3D printers, you can pay as little or as much as you would like. For a simple desktop printer, there are some great options in the $3,000 to $5,000 range. If you are willing to compromise on build volume or are up to the challenge of building your own printer from scratch, there are even a few options in the $300 to $1,000 range. Of course, moving up the scale, there are a number of industrial printers in the hundreds-of-thousands to million-dollar range.

As you might imagine, with such a wide range of price points, the capabilities of the printers vary dramatically. As a starting point, consider how much you would like to budget for a printer, and then determine whether or not there is a machine that will accomplish your organizational goals within your budgetary constraints.

Do you have the necessary infrastructure in place?

When it comes to incorporating 3D printing into your work environment, there are several factors that you need to think about:

Space

One of the first things you should consider before shopping for a printer is whether or not you have the space. While modern desktop printers are relatively compact, they still require some room. As you move up into larger industrial machines, the space requirements can grow considerably.

In addition to the necessary space for the printers themselves, you also require storage space for filament, extra print heads, and any accessories, such as scanners, that you might also opt to purchase. If you are interested in a printer with dissolvable filament, you will need to make sure that you also have space for the support removal system.

Electrical Requirements

Every printer has different electrical requirements. Before purchasing a specific printer, it is important to make sure that you are able to install any dedicated outlets that you may require.

Water

If the printer you have chosen is a dual head with disposable filament, you will need easy access to water to fill the tank and rinse off your parts.

Ventilation

Ventilation needs can vary quite significantly from one type of printer to the next. If you choose a type of printer that requires chemicals to finish the parts, you have to have a space that is very well ventilated.

What exactly would you do with a printer right now?

Before you make the final decision to purchase a printer, you want to make sure that you have a solid plan as to how you are going to use the printer. All too often, companies rush into purchasing a printer because they think that it is cool or they want to keep up with the next big thing. This is not a reason to purchase a printer. While I can absolutely guarantee that you will find a whole slew of uses for your printer that you don’t currently anticipate, you want to come out of the gate with a plan for putting your printer into immediate action. Figure out where your pain points lie and make sure that you have a clear understanding of both the power and the limitations of 3D printing technology. Start off with a solid plan, and your printer will begin to pay dividends from the start.

How often do you anticipate using the printer?

This question will help you decide which type of printer is the best for your organization. If you view a printer as something that will come in handy every once in a while, you may opt for a less expensive model to shorten your ROI timeframe. Keep in mind, however, that less expensive printers often require more time and effort to achieve the print quality that you desire.

If, on the other hand, you are looking for a workhorse of a printer that you can run around the clock relatively unassisted, you are venturing into higher-end printer territory. With higher-end printers, however, better tolerances and greater reliability can also go a long way toward speeding up the timeframe for your ROI.

Do you have the proper staff in place?

If you don’t know how to use a 3D printer, it has no better benefit to your organization than as an expensive coffee table.

I am going to assume that you have the design part of the 3D printing equation under control. But, just because you know how to create the design in Fusion 360, or Inventor, or whatever other 3D modeling program you prefer to work with, it doesn’t mean that you know how to print your design properly.

The first thing that you are going to have to learn is your specific printer’s optimal settings. Unfortunately, this often is a matter of trial and error, as the manufacturer’s settings are rarely just what you are looking for.

Another thing that can greatly affect your print quality is the printing software. Anybody who expects to have a good quality print must be very familiar with their splicer, their mesh tools, and their printer desktop.

If your staff isn’t prepared to take on the challenges of a 3D printer, you will have to consider whether you need to bring in additional staff or purchase training for your current staff.

When a design organization implements a 3D printing program correctly, it almost always pays dividends quickly. Giving your engineers and designers the chance to experiment more, try out design iterations, and find out quickly what works and, more importantly, what doesn’t, makes your organization nimbler and helps to get your products to market or your models to your customers faster. But, in order to get the most benefits out of your 3D printer, you have to make sure that you have the answers to important questions like, “Does a 3D printer fit within my budget?” “How will my organization use a 3D printer?” and “Do I already have the space and employees to start a 3D printing program, or will we have to expand the organization?”

Being able to answer these questions, along with having a good understanding of how to implement a 3D program, as well as the costs and benefits of various types of printers, will help ensure that your organization benefits from the immense potential of 3D printing.

Steven Schain is the postproduction supervisor for all CADLearning products from 4D Technologies, specializing in the development of Media & Entertainment CADLearning products for Autodesk, Inc., software, including 3ds Max software and Maya software.