Description

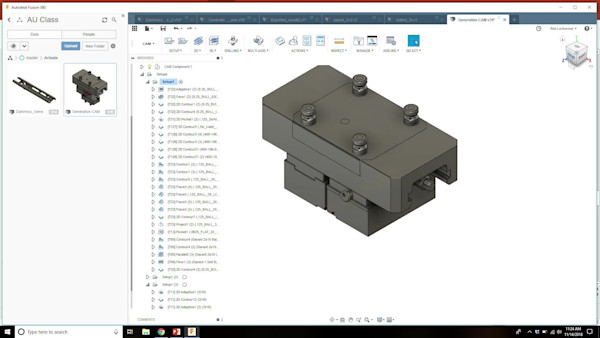

While generative design offers innovative, organic forms, its realization has largely been limited to prototyping via additive manufacturing. Conventional computer numerical control (CNC) Machinist, despite its advancements and suitability for mass production, has primarily focused on geometric parts, alongside making the production more efficient, autonomous, and lights out. This project investigates a paradigm shift by exploring the integration of generative design with modern CNC Machinist techniques. We’ll delve into recent developments in CAM software, using Autodesk Fusion 360 software and modern CNC techniques that enable the fabrication of complex, freeform designs developed through generative algorithms. By examining a successful case study of bicycle components, current limitations, and potential applications across various industries, this presentation aims to highlight the potential of this integrated approach to bring generative design to mass manufacturing, moving beyond prototyping and into real-world applications.

Key Learnings

- Learn how Autodesk Fusion 360 combines generative design and CAM simulation to create complex toolpaths for organic freeform designs.

- Discover how the Fusion 360 tools bridge the gap between generative design and modern manufacturing processes.

- Explore a case study to see how generative design can be integrated with advanced CNC Machinist.

- Learn how generative design principles optimize product innovation and efficiency in mass manufacturing.

Downloads

Tags

Product | |

Industries | |

Topics |

People who like this class also liked

Industry Talk

Get Up to Speed with Automotive Manufacturing

Instructional Demo