설명

Dragon Innovation wrote the book on manufacturing at entrepreneur speed. In this class, we'll discuss how hardware teams can see into their manufacturing future with a well structured Bill Of Materials, avoiding costly mistakes as they move from prototype to production.

주요 학습

- Understand the importance of a well structured Bill of Materials as you transition from design to manufacturing

- Understand the type of manufacturing insights you can get when you have the right data

- Increase practical knowledge of the pitfalls going from prototype to production

- Discover how Dragon has satisfied an unserved market need and incorporated Forge Platform APIs

Downloads

태그

산업 분야 | |

주제 |

이 수업을 좋아하는 사람들은 다음도 좋아했습니다.

Autodesk Product Briefing

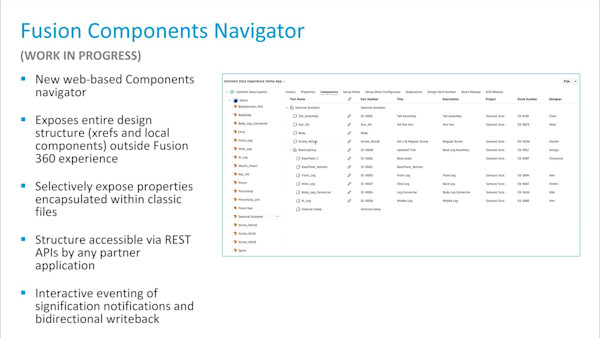

Forge Road Map: Fusion 360 on Forge Data

Instructional Demo

More Tips, Tricks, and the Future of the Forge Model Derivative Service

Instructional Demo

Power-Ups and Cheat Codes: Tips and Tricks for the Fusion 360 API

Industry Talk